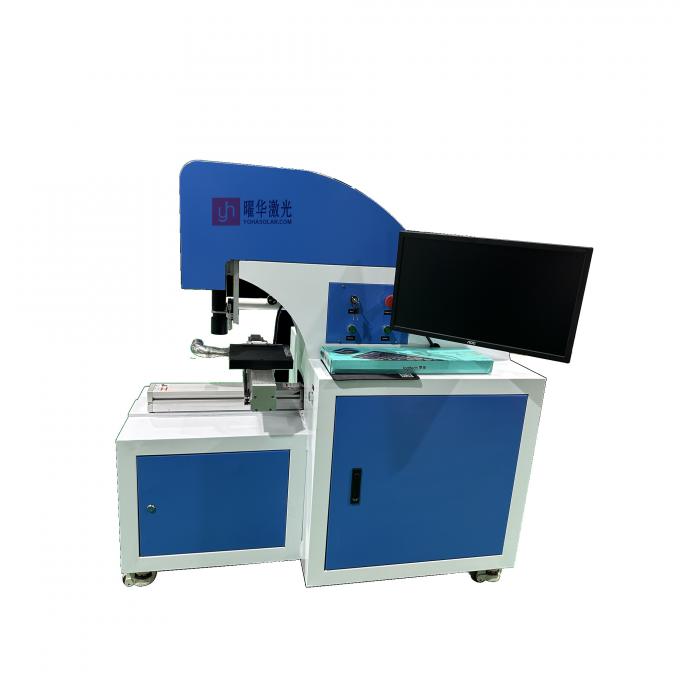

Semi Automatic Solar Cell Laser Scribing Machine

Technical specifications:

Application:

Designed for precise cutting and scribing of solar semiconductor silicon wafers, ceramic wafers, and other delicate materials, ensuring high accuracy and minimal damage to the surfaces, making it ideal for various advanced manufacturing processes in the semiconductor and solar industries

Features:

1. Laser scribing machine is a kind of equipment integrating light, machine and electricity;

2. 1064nm fiber laser is used as the laser source;

3. The fiber laser has a very high degree of integration, the optical path is fully enclosed, and no consumables, maintenance-free, long life, good optical quality (㎡ <1.3) and high reliability;

4. Small size, fast processing speed and low power consumption;

5. Novel appearance, reasonable structure, easy to operate, high precision and stable performance.

Specifications:

| Specifications | Description |

| Service Life | ≥ 100,000 hours |

| Energy Consumption | ≤ 1000W |

| Electro-Optical Conversion Efficiency | ≥ 35% |

| Laser Output Mode | Fundamental mode |

| Power Stability | ≤ 3% |

| Warranty Period | ≥ 1 year |

| Equipment Size | 1300mm * 760mm * 1350mm |

| Equipment Weight | 600kg |

Technical Parameter:

| Laser Source: | 1064nm fiber laser |

| Beam quality: | ㎡ <1.3 |

| Worktable stroke: | 700mm*400mm |

| Maximum scribing speed: | 600mm/s |

| Scribing precision: | ≤0.02mm |

| Cooling system: | air-cooled |

| Scribing width: | ≤0.03mm |

| Scribing structure: | double-station scribing |

| Scribing table: | glass table |

| Cutting efficiency: | <1500pcs/h |

| Number of loading trays: | 2pcs/double-station loading |

| Cell size: | 125/156/166/182/210mm whole cell, non-standard cell, rice grain cell, missing corner cell |

| Compressed air: | 0.5-0.8MPa |

| Input voltage: | 220VAC/50HZ |

| Machine power consumption: | 1000W |

Environmental requirements:

1. Clean and Dust-Free Working Environment

The machine requires a clean and dust-free working environment to ensure optimal performance and avoid any interference with its precision. Contaminants in the air can affect the quality of operation, so maintaining a controlled and sterile environment is essential.

2. Temperature Control of 5℃ to 30℃ and Humidity Below 75%

The machine should be operated in a temperature-controlled environment, with temperatures maintained between 5℃ and 30℃, and humidity levels kept below 75%. This ensures stable performance and helps prevent potential issues related to material expansion, contraction, or electrical performance.

3. Recommended Use in an Air-Conditioned Workshop

To maintain a consistent operating environment, it is strongly recommended that the scribing machine be used in a workshop equipped with air conditioning. This will help regulate temperature fluctuations and provide a stable climate for the machine’s operation.

4. No Strong Vibration or Magnetic Sources Near Installation Area

The installation area must be free from sources of strong vibrations or powerful magnetic fields, as these can adversely affect the machine’s precision and functioning. Ensuring that these external factors are minimized helps maintain the accuracy and longevity of the equipment.

| Feature | Description |

| Working Environment | Clean And Dust-Free |

| Temperature | 5-30℃ |

| Humidity | <75% |

| Workshop | Air-Conditioned |

| Installation Area | No Strong Variation or Magnetic Sources |